Steel Reinforced Polyethylene Plastic Pipes (SRPE) steel skeleton plastic composite pipe

Brand Jingtong

Product origin Tianjin China

Delivery time 30days

Supply capacity 100000tons/year

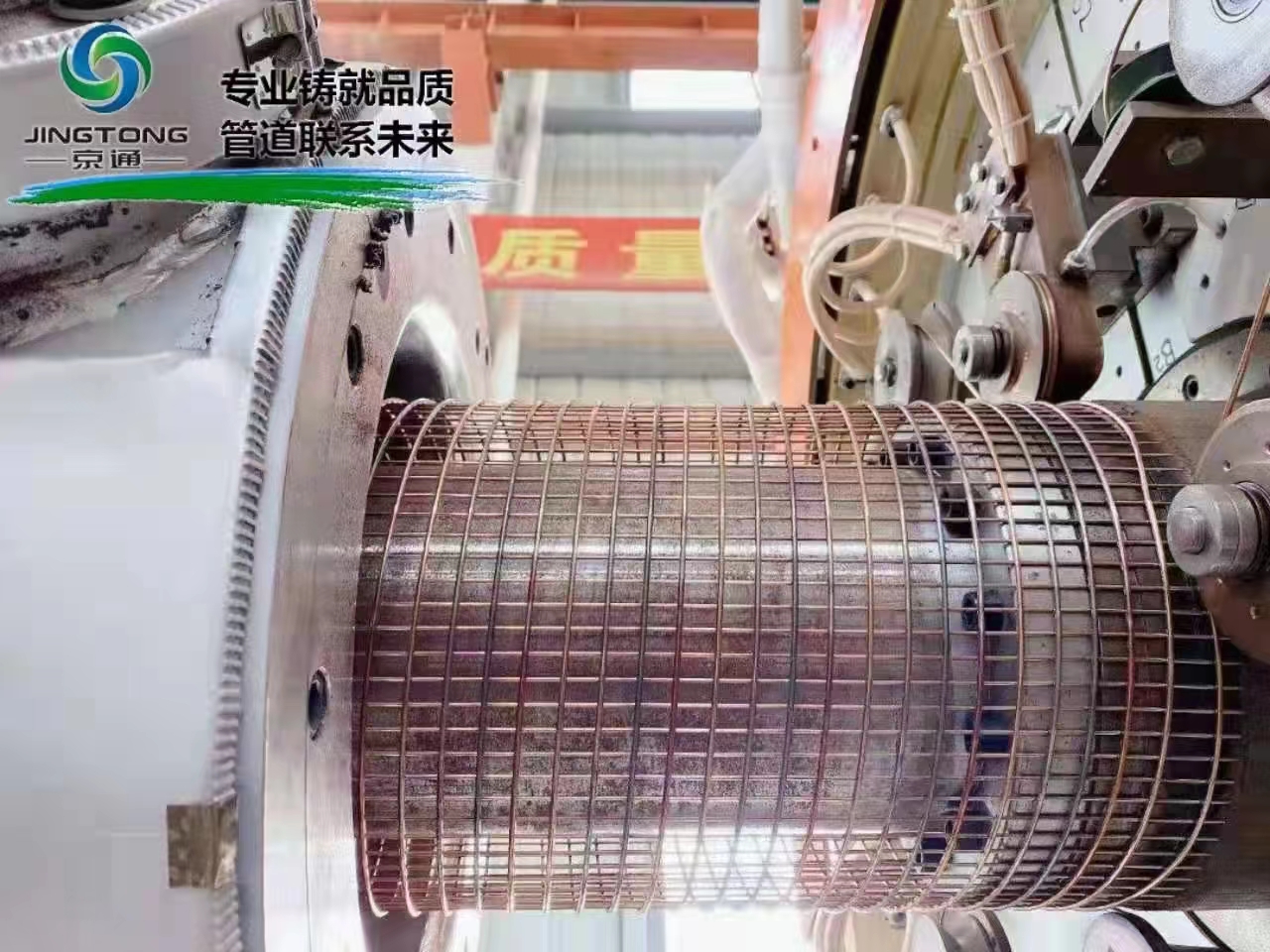

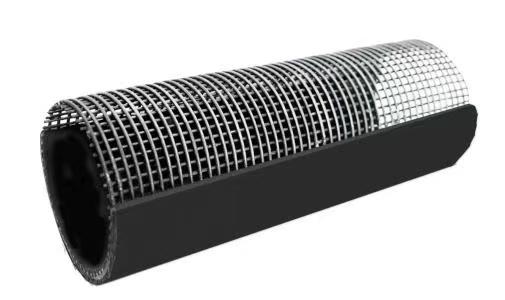

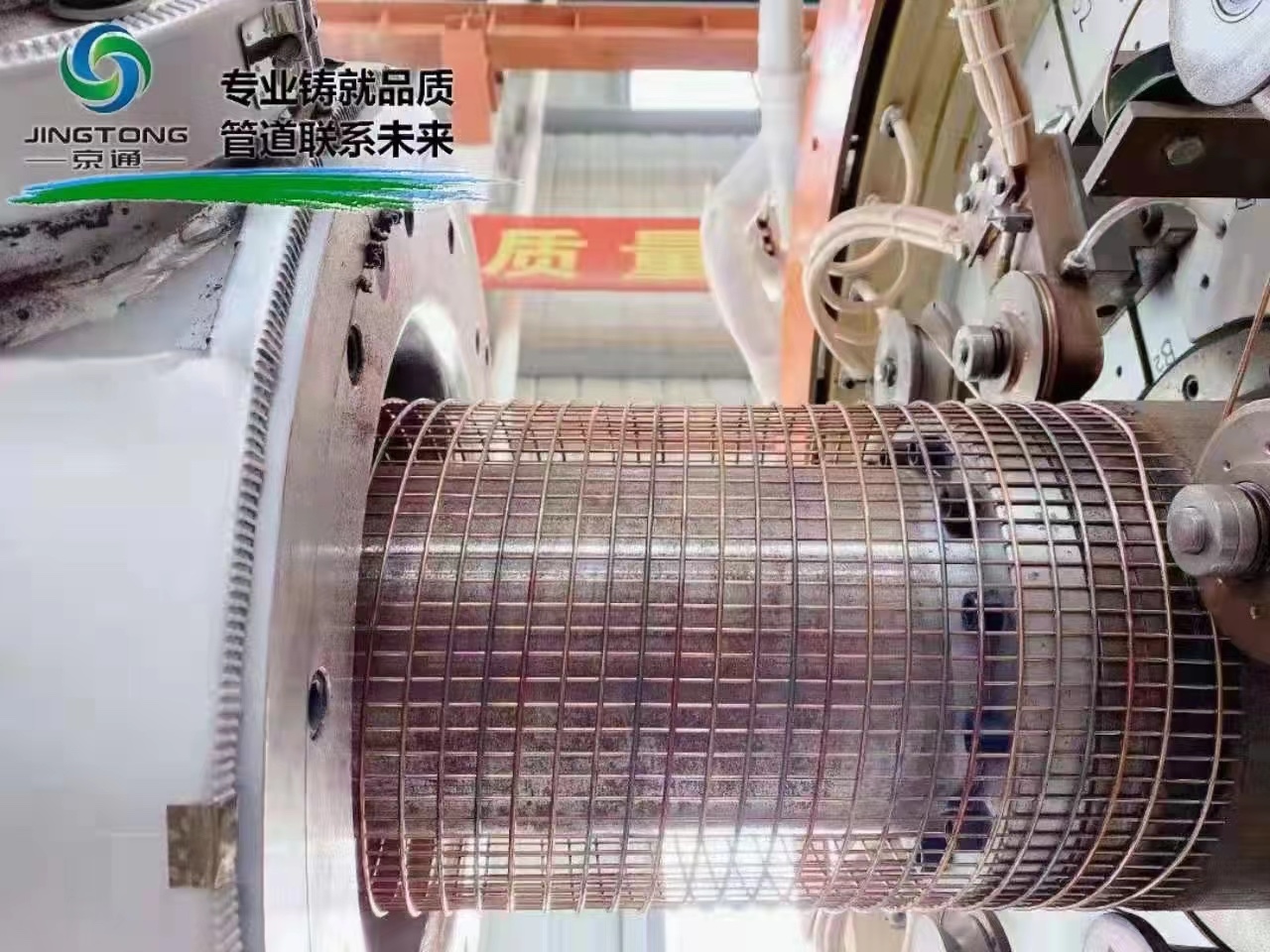

Steel Reinforced Polyethylene Plastic Pipe, Using High Density Polyethylene (HDPE) as the material for the framework, strong steel skeleton are made the framework to create a high tensile strength to strengthen the body.The use of HDPE as the raw material results in a lightweight pipe that resists aggressive chemicals, withstands freeze-thaw cycles and continuous subzero temperatures without cracking. HDPE is also highly abrasion-resistant and is unaffected by acidity or alkalinity.But that is not all - fuse HDPE with strong steel skeleton and a lightweight, flexible pipe is now granted higher tensile strength and durability. Best of all, with our dedicated low-cost electro-fusion fittings for inter-pipe connections, trouble-free installation remains uncompromised.

Steel Reinforced Polyethylene Plastic Pipe,

Using High Density Polyethylene (HDPE) as the material for the framework, strong steel skeleton are made the framework to create a high tensile strength to strengthen the body.The use of HDPE as the raw material results in a lightweight pipe that resists aggressive chemicals, withstands freeze-thaw cycles and continuous subzero temperatures without cracking. HDPE is also highly abrasion-resistant and is unaffected by acidity or alkalinity.But that is not all - fuse HDPE with strong steel skeleton and a lightweight, flexible pipe is now granted higher tensile strength and durability. Best of all, with our dedicated low-cost electro-fusion fittings for inter-pipe connections, trouble-free installation remains uncompromised.

Pipe Details:

l 1.Material: high density polyethylene,steel wires

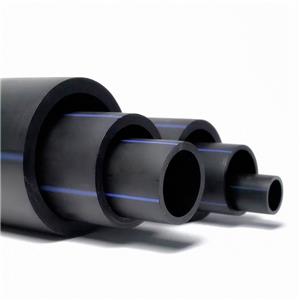

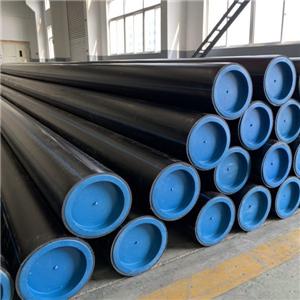

l 2.Sizes: from 50mm to 600mm

l 3.Thickness: from 9.0mm to 20mm

l 4.Length:6m,12m

l 5.Colors:black with blue stripe

l 6.Connection: electrofusion joint

l 7.Certification: ISO9001, ISO14001

l 8.Standard: CJ/T123-2016

l 9.Applications: water supply and other liquid

l 10.Delivery time:About 5-15 days after payment

11.Terms of payment:L/C,T/T

12.Price terms:FOB ,CFR,CIF

Advantages

l 1. corrosion resistance;

l 2. Resistant to chemical fertilizers and herbicides;

l 3. Nontoxic and odorless;

l 4. Resistant to harsh climate;

l 5. Up to 50 years' durability;

l 6. Resistant to deformation;

l 7 Smooth interior structure, lowfriction losses;

l 8. Lowlabor cost for handling and installing;

l 9. Reliable performance and easy maintenance.

Applications

The steel skeleton plastic composite pipe is composed of the imported high quality HDPE matrix and the steel mesh skeleton, which not only has the strength of the steel pipe, but also has the excellent corrosion resistance of the plastic pipe. It has more obvious advantage in the technical performance than the other pipes, and the performance price ratio is high. The excellent comprehensive performance of the steel frame plastic composite pipe determines its safety and reliability and economy. It can not only meet the requirements of the common plastic pipe, but also replace the stainless steel and other metal anticorrosive pipes, and to a wide range of applications.

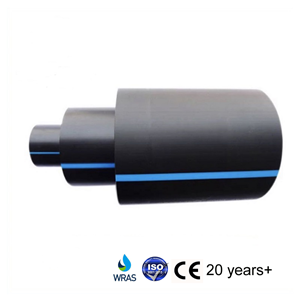

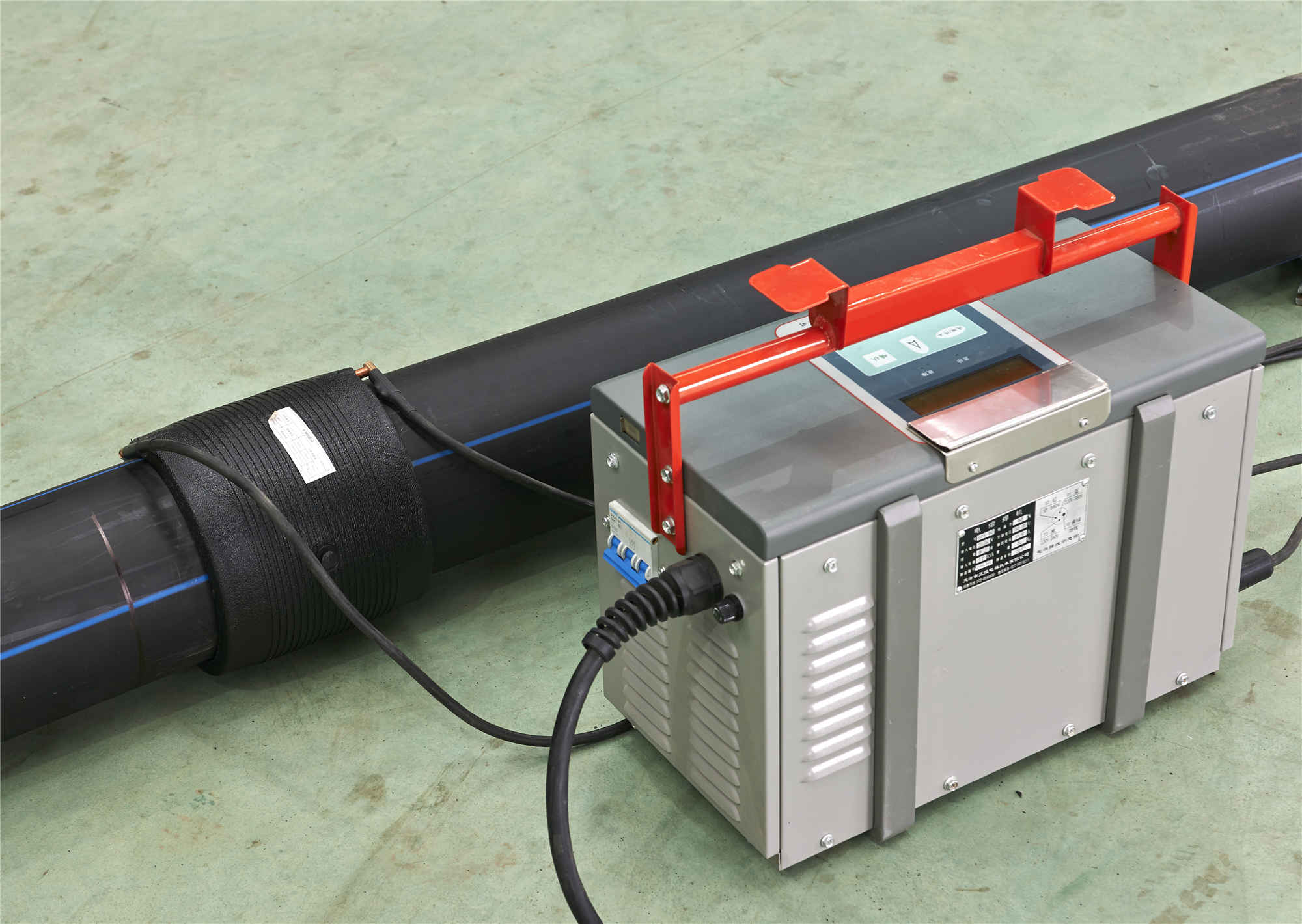

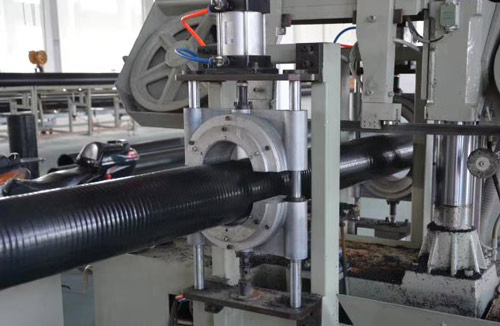

Pipe Connection

SRPE pipe normally use Electro-fusion to joint the pipelines.The electric melting sleeve includes two forms, pure plastic electrofusion and frame melting. They are suitable for different working conditions. Our engineering and technical personnel can help users choose according to the best performance price ratio.

Pipe Specification

Speci DN/ID | Mean ID tolerance | Normal Pressure PN/MPa | the distance of steel wire to pipe inside and outside wall | ||||

1.0 | 1.6 | 2.0 | 2.5 | 4.0 | |||

Pipe wall thickness | |||||||

50 | ±1 | — | — | — | 9.0 | 10.6 | ≧1.8 |

65 | — | — | — | 9.0 | 10.6 | ||

80 | — | — | — | 9.0 | 11.7 | ||

100 | — | 9.0 | 9.0 | 11.7 | 11.7 | ||

125 | — | 10.0 | 10.0 | 11.8 | 12.3 | ||

150 | 12.0 | 12.0 | 12.0 | 12.0 | 15.5 | ||

200 | 12.0 | 12.0 | 12.5 | 12.5 | — | ||

250 | ±0.8 | 12.0 | 12.5 | 12.5 | 13.0 | — | ≧2.5 |

300 | 12.5 | 12.5 | 12.5 | — | — | ||

350 | 15.0 | 15.0 | 15.5 | — | — | ||

400 | ±0.5 | 15.0 | 15.0 | 15.5 | — | — | ≧3.0 |

450 | 15.5 | 16.0 | 16.5 | — | — | ||

500 | 15.5 | 16.0 | 16.0 | — | — | ||

600 | 19.0 | 20.0 | — | — | — | ||

Reduction coefficient of working temperature on maximum working pressure of pipes

Temperature,t/℃ | 0<t≤20 | 20<t≤30 | 30<t≤40 | 40<t≤50 | 50<t≤60 | 60<t≤70 | 07<t≤80 |

Reduction coefficient | 1.00 | 0.95 | 0.90 | 0.86 | 0.81 | 0.76 | 0.60 |

Connection

SRPE pipe connection is through electro fusion fittings

Fittings

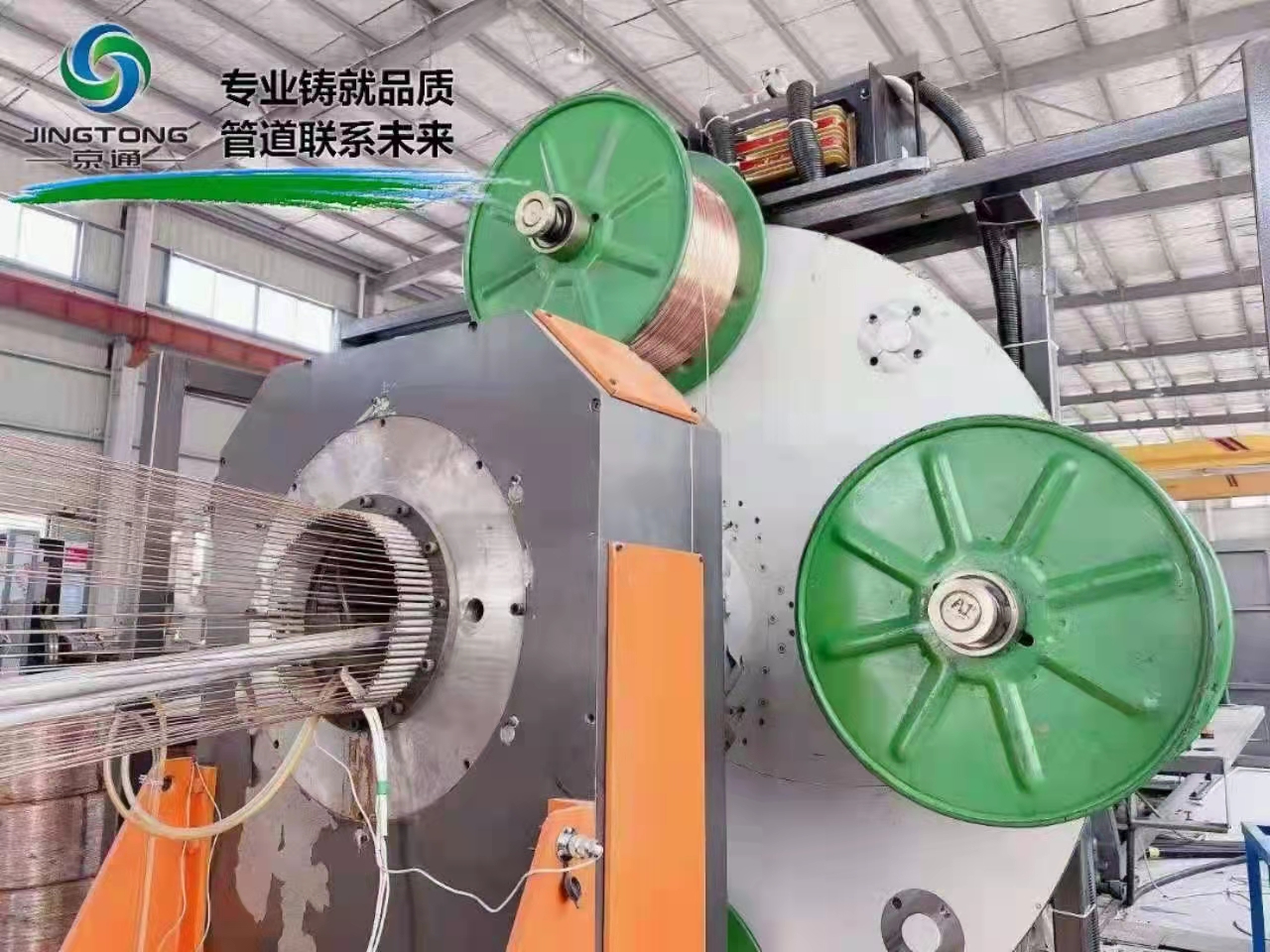

Production:

Application